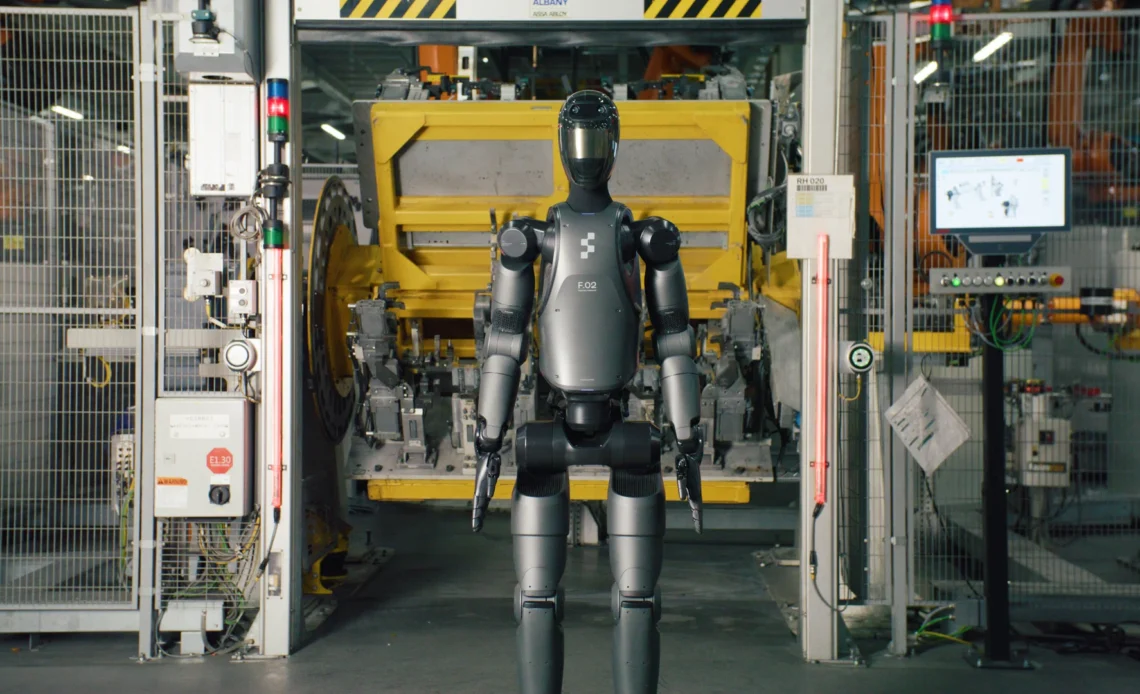

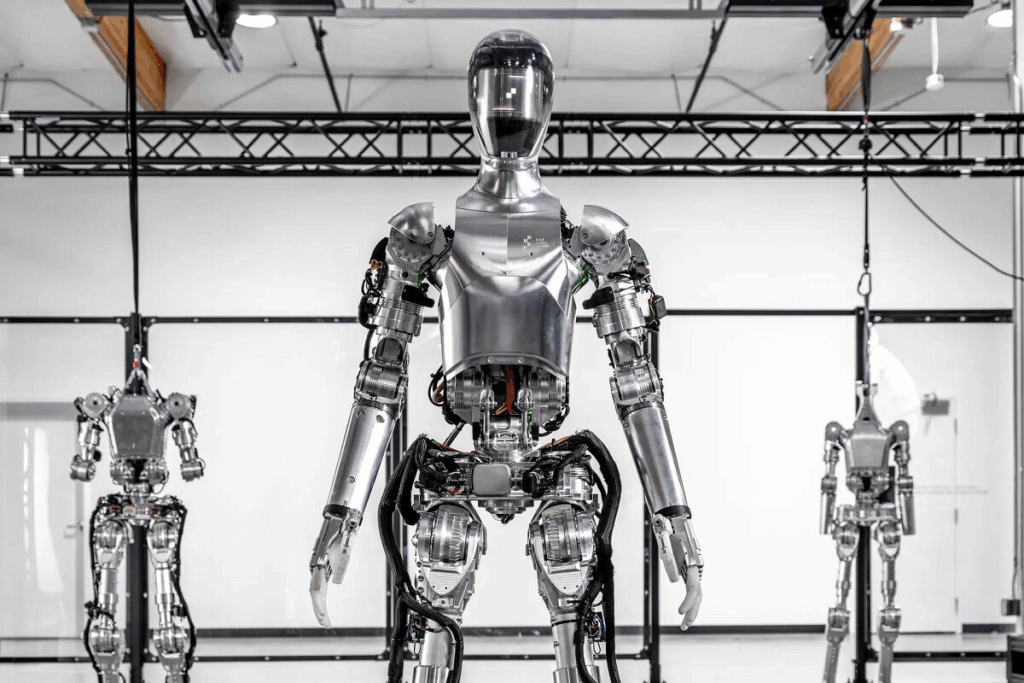

🤖 A video from a BMW plant has become a true symbol of the new industrial era (the video clip can be seen on our Telegram channel). What we see is not just another robotic arm tightening bolts in a set sequence, but a bipedal robot — a two-legged worker standing alongside humans on the assembly line, performing tasks that require coordination, reaction, and adaptation. This is not a tech demo for marketing purposes — it’s a fundamental shift in what’s now possible in manufacturing.

The main barrier that has long slowed automation wasn’t the price of hardware — it was flexibility. Industrial arms could perform the same task with perfect precision, but as soon as a part changed or conditions shifted slightly, the system required reprogramming, new sensors, and another setup cycle. A human, by contrast, could adapt instantly. That’s why China, India, and Vietnam remained the strongholds of “flexible cheap assembly” — where human ingenuity and low labor costs compensated for variability in production.

Now the equation is starting to change. Let’s look at the economics:

- Average hourly wage of a worker in the U.S. — $20-30.

- In Europe — €18-28.

- In China — $4-7.

- Operating an industrial robot — $2-4.

- And for bipedal universal robots, once mass deployment begins, the cost may drop below $2 per hour.

That means that for the first time in history, the flexibility and versatility once unique to humans are becoming available to machines — and at a lower cost.

Previously, the idea of “bringing manufacturing back home” fell apart under simple arithmetic. An American or German factory with high labor costs couldn’t compete with a Chinese one — not in quality, but in economics. Yes, robots could be installed, but they couldn’t handle constant changes — the human factor in Asia remained a key advantage.

Now, if a robot can independently adapt to a new task, work side by side with humans, change tools, recognize objects, and learn on the job — the last reason to keep assembly lines in China disappears.

The effect will be avalanche-like.

- Logistics shorten.

- Production cycles become faster.

- Control and innovation move closer to headquarters.

- And most importantly — the economics of production stop depending on wage differences.

For China, this is a warning sign. Its industrial strength has been not only scale but the flexibility of cheap labor. If robots can provide that same flexibility — and at a lower hourly cost — “cheap Asia” will no longer be necessary.

And that’s where a true industrial revolution begins: when the location of production is determined not by cheap labor, but by delivery speed, quality control, and the ability to adapt products quickly.

💡 BMW has simply shown the world that this moment has arrived.

All content provided on this website (https://wildinwest.com/) -including attachments, links, or referenced materials — is for informative and entertainment purposes only and should not be considered as financial advice. Third-party materials remain the property of their respective owners.